CY-K6150B CNC Lathe (1M)

Application Scenarios

- Precision Machining: Turning shafts, sleeves, flanges, and threaded parts with high accuracy for automotive, aerospace, and medical device industries.

- Automotive Parts Production: Batch machining of engine components, gear shafts, and brake parts with consistent quality.

- General Machinery Manufacturing: Processing medium-sized mechanical parts like hydraulic cylinders and pump bodies for industrial equipment.

- Energy & Instrument Sectors: Fabricating precision parts for energy devices and high-precision instruments.

- Small to Medium Batch Production: Ideal for production lines requiring automation, efficiency, and repeatable precision in limited workspace.

Supplementary Notes

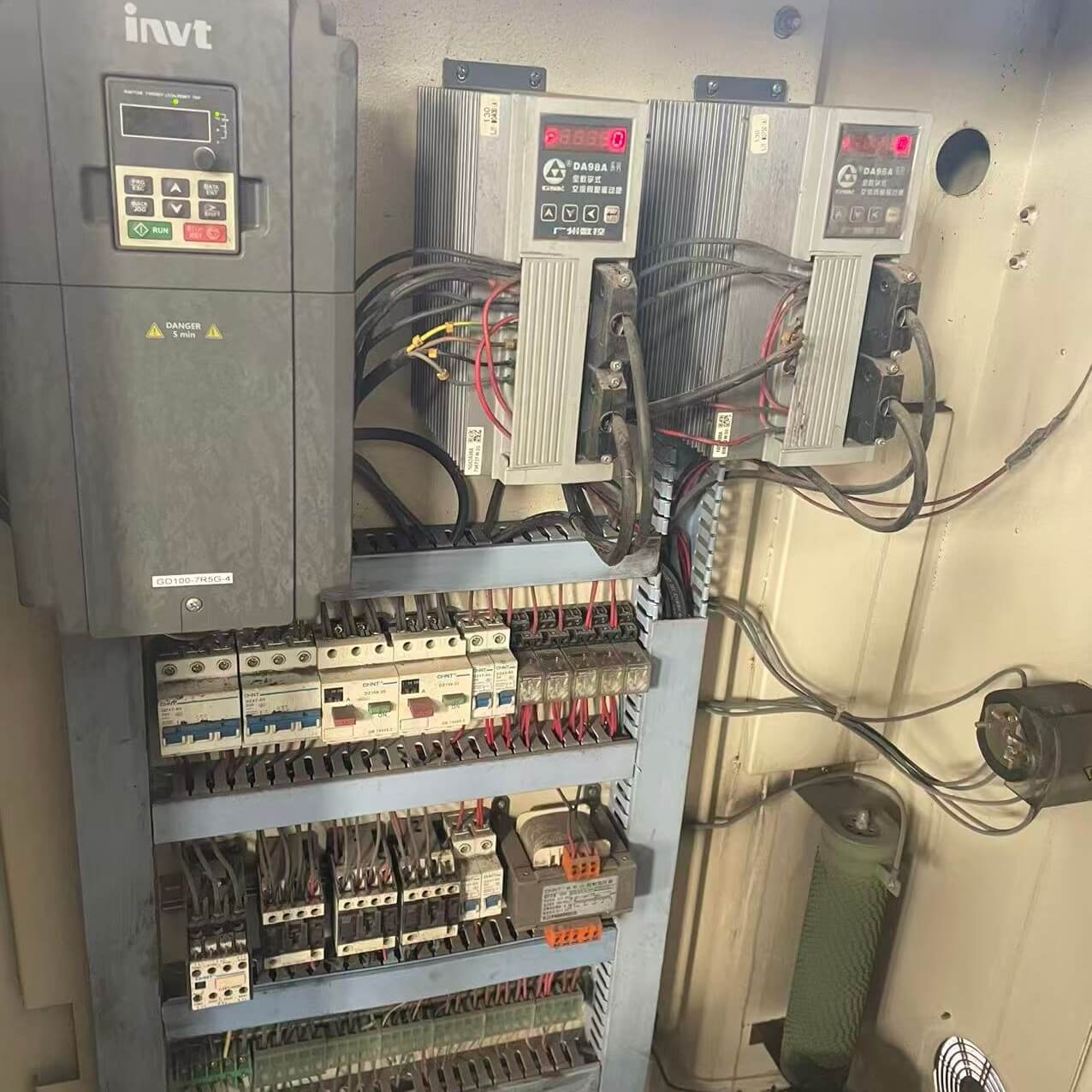

- Equipment Features: Rigid bed for heavy cutting; CNC control enables automated multi-process machining; turret tool post supports complex part processing in one setup.

- Applicable Materials: Carbon steel, alloy steel, stainless steel, non-ferrous metals (aluminum, copper), and engineering plastics.

- Industries Served: Aerospace, automotive, energy, general machinery, and precision instrument manufacturing.

4,299.00$

Core Parameters

- Bed Length: 1000mm (1m)

- Maximum Workpiece Diameter: 500mm

- Maximum Workpiece Length: 800mm (effective machining length)

- Spindle Speed Range: 50-2000rpm (stepless or multi-gear)

- Spindle Through Hole Diameter: 80mm

- X-axis Travel: 230mm

- Z-axis Travel: 800mm

- Rapid Traverse Speed (X/Z): 8/12 m/min

- Feed Rate Range: 0.01-5mm/r

- Tool Post Quantity: 8-station turret (optional 12-station)

- CNC System: FANUC, SIEMENS, or domestic systems (GSK/KND)

- Main Motor Power: 11kW

- Machine Weight: Approx. 3800kg

- Positioning Accuracy (X/Z): ≤0.015/0.02mm

- Repeatability Accuracy (X/Z): ≤0.01/0.015mm

Don’t miss your opportunity-our best machines go fast.