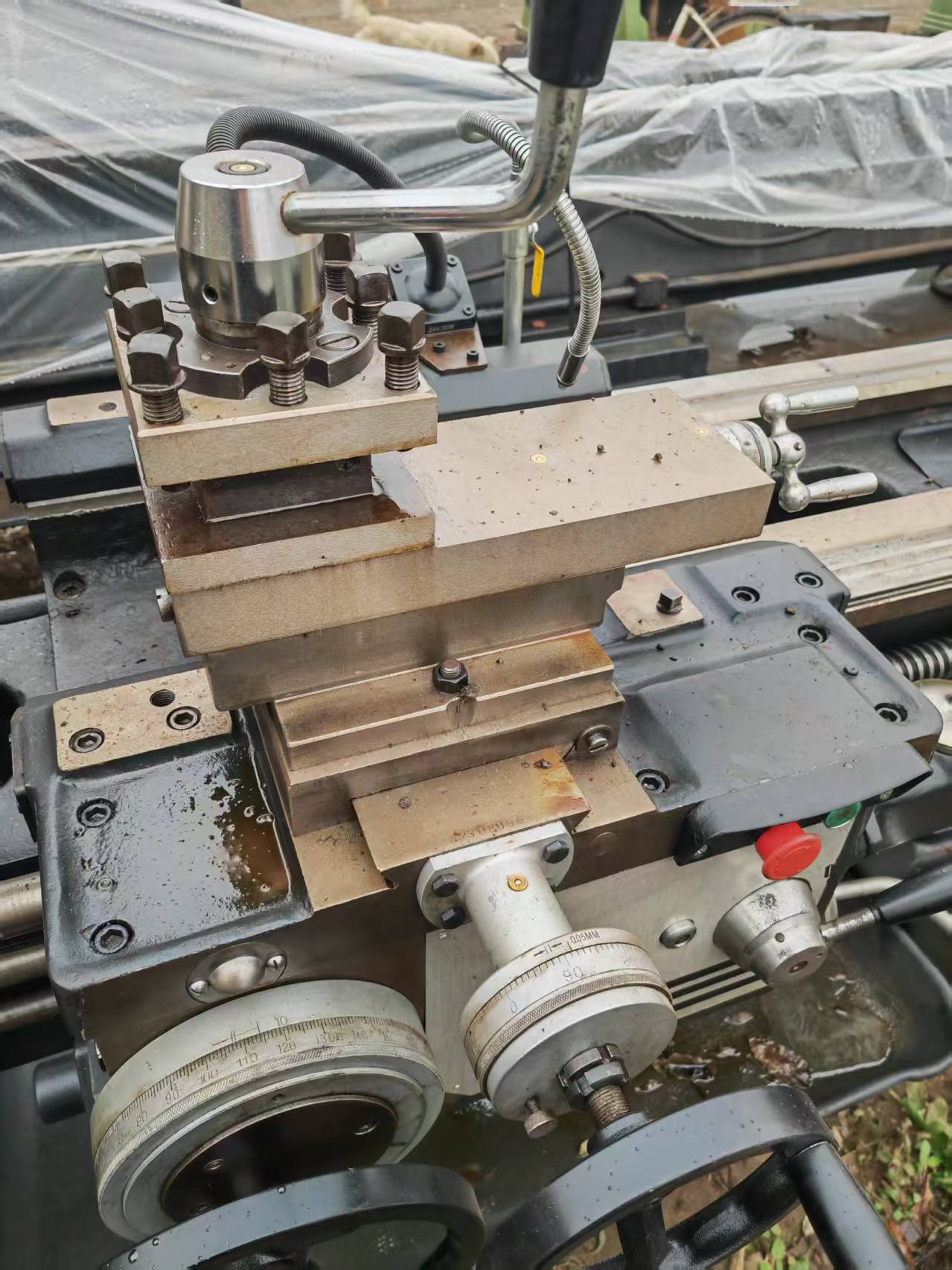

Shenyang CA6261 Lathe

- Exceptional Structural RigidityThe bed, headstock, and saddle are crafted from high-strength gray cast iron (HT300) and undergo double aging treatment (natural + artificial) to eliminate internal stress. This minimizes deformation during heavy-duty cutting, ensuring stable machining of large workpieces (e.g., shafts, discs with diameter up to 610mm).

- High Machining Precision & Durability

- The spindle is supported by precision class P4 rolling bearings, reducing radial runout to ≤0.008mm and axial runout to ≤0.005mm.

- Guide rails feature quenching (surface hardness HRC52-58) and precision grinding, with low friction coefficient and wear resistance—maintaining positioning accuracy for long-term use.

- Versatile Machining CapabilitiesWith a wide range of spindle speeds (8-1250r/min) and feed rates, it accommodates diverse processes: turning, boring, facing, threading (metric/inch), and grooving. It works seamlessly with materials like carbon steel, alloy steel, cast iron, and non-ferrous metals, fitting general machinery, automotive, and heavy equipment industries.

- Stable & Low-Maintenance Operation

- The transmission system uses high-precision gears (modulus ≥3) with carburizing and grinding, ensuring smooth power transfer, low noise (<75dB), and minimal wear.

- Centralized lubrication system automatically delivers oil to guide rails, lead screws, and bearings, reducing manual maintenance and extending component lifespan.

3,800.00$

High precision and stability: Utilizing high-strength cast iron, with special materials such as copper and chromium added, the bed guideway width is 400mm, and the quenching depth of the bed guideway reaches 4mm. This effectively enhances the wear resistance and stability of the machine tool.

| Attribute Category | Specific Item | Specification | Unit |

|---|---|---|---|

| Basic Information | Model | CA6261 (Horizontal Lathe) | - |

| Basic Information | Machine Type | Heavy-Duty General-Purpose Lathe | - |

| Machining Capacity | Max Swing Diameter Over Bed | 610 | mm |

| Machining Capacity | Max Swing Diameter Over Cross Slide | 380 | mm |

| Machining Capacity | Max Processing Length (Optional) | 1500 / 2000 / 3000 / 5000 | mm |

| Spindle System | Spindle Speed Range | 8 - 1250 | r/min |

| Spindle System | Spindle Bore Diameter | 80 | mm |

| Spindle System | Spindle Taper Hole | Morse No.7 | - |

| Tool Post System | Tool Post Type | 4-Station Square Turret (Manual) | - |

| Tool Post System | Max Tool Shank Size | 40×40 | mm |

| Feed System | Longitudinal Feed Rate Range | 0.06 - 12.5 | mm/r |

| Feed System | Cross Feed Rate Range | 0.03 - 6.25 | mm/r |

| Power System | Main Motor Power | 11 / 15 (Optional) | kW |

| Power System | Cooling Pump Power | 0.37 | kW |

| Structural Dimensions | Overall Dimensions (L×W×H, 1500mm length) | approx. 4200×1800×1600 | mm |

| Structural Dimensions | Net Weight (1500mm length) | approx. 5800 | kg |

Don’t miss your opportunity-our best machines go fast.