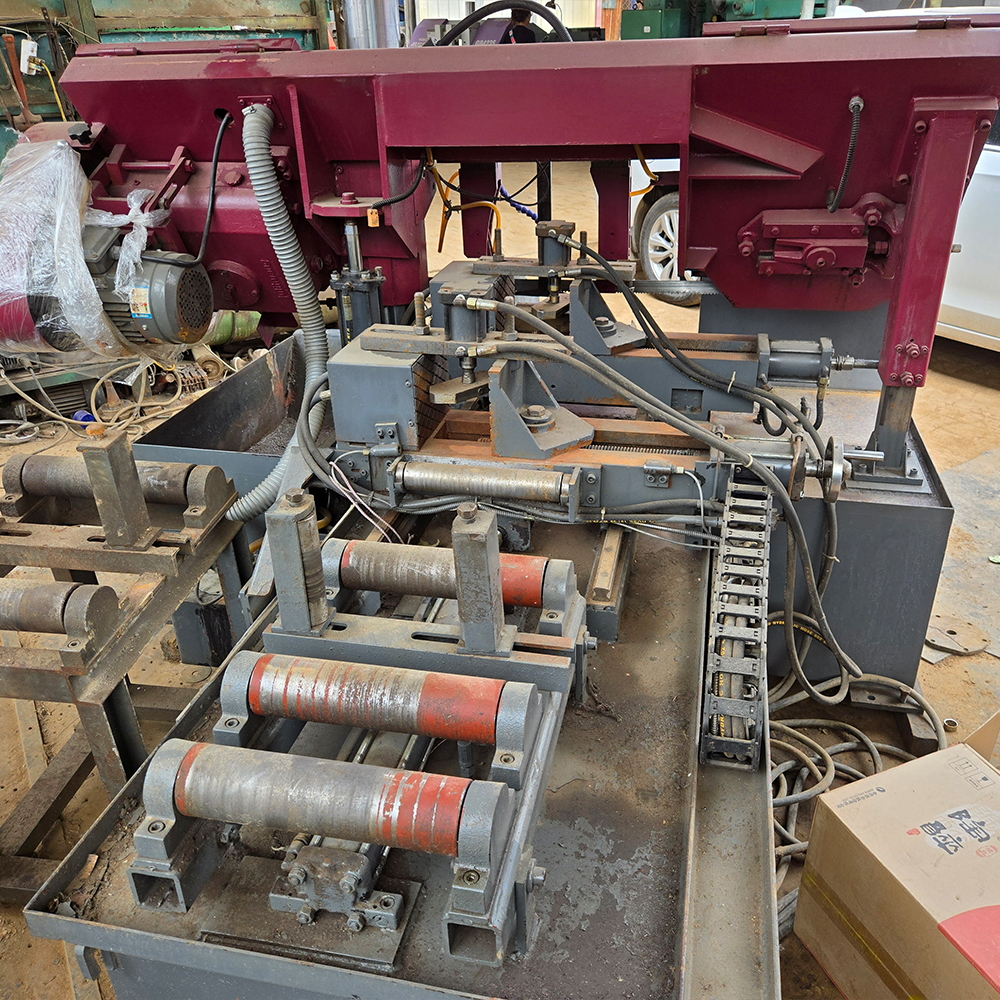

Band Saw Machine GB4028

GB4028 is a hydraulic semi-automatic horizontal metal band saw, primarily used for cutting small to medium-sized metal materials. It is suitable for the blanking needs of various fields such as machinery manufacturing and hardware processing. Specific applications are as follows:

I. Core Application Areas

* **General Machinery Manufacturing Blanking:** Provides blanks for lathes, milling machines, grinding machines, etc., such as cutting blanks for shaft parts (motor shafts, drive shafts) and sleeve parts.

Suitable for batch blanking in machine tool parts and mechanical component production, consistently ensuring the perpendicularity and dimensional accuracy of the cut surface.

**Automotive and Parts Industry:** Processes initial blanks for automotive half-shafts, steering knuckles, gear blanks, etc., and can also cut raw materials such as steel pipes and round steel for subsequent processing.

The smoothness of hydraulic transmission meets the efficiency and consistency requirements of batch production of automotive parts.

**Construction Machinery and Agricultural Machinery:** Cuts blanks for construction machinery parts such as pins, bushings, and connecting rods, as well as raw materials (round steel, square steel) for agricultural machinery drive shafts and sprockets.

Capable of cutting common engineering materials such as low- and medium-carbon steel and cast iron, and adaptable to the initial blanking requirements of high-strength parts.

Hardware Tools and Standard Parts Production: Cutting raw materials for standard parts such as bolts, nuts, and lead screws, as well as blanking for hardware tools (wrenches, screwdriver handles).

Semi-automatic control reduces manual intervention, suitable for efficient blanking of small to medium batches of standard parts.

Mold and Tooling Fixture Manufacturing: Cutting raw materials for mold guide pillars, guide sleeves, ejector pins, and other accessories, as well as blanks for tooling fixture positioning shafts and clamping sleeves.

High cutting accuracy (cutting perpendicularity error ≤ 0.2mm/m), reducing waste in subsequent processing.

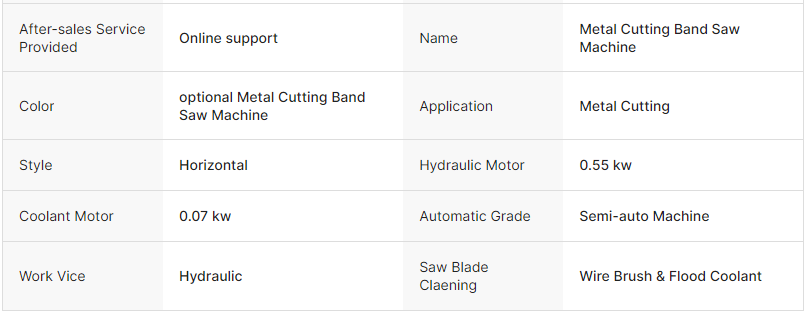

II. Compatible Processing Materials and Specifications: Compatible materials: Primarily low- and medium-carbon steel and cast iron, but also capable of processing non-ferrous metals such as stainless steel, copper, and aluminum, and some low-alloy high-strength steel (requires selection of appropriate saw blades).

Processing Specifications: Maximum sawing diameter for round steel: 280mm; maximum cross-section for square steel/plate: 280mm×280mm; length adjustable according to the feeding device (manual feeding or optional automatic feeding mechanism).

III. Application Advantages and Suitable Scenarios: Hydraulic semi-automatic control ensures stable sawing, suitable for small to medium batch cutting, with 3-5 times higher efficiency than manual saws.

Adjustable saw blade tension results in a clean cut, reducing subsequent processing allowances, suitable for scenarios requiring high cutting precision (such as precision parts blanks).

Compact structure and simple operation make it suitable for the daily cutting needs of small to medium-sized factories, workshops, and individual processors.

3,000.00$

Don’t miss your opportunity-our best machines go fast.