CNC lathe QK1319

Core Application Scenarios

The QK1319 CNC lathe is a high-precision, professional CNC pipe threading lathe, specifically optimized for processing long and thin workpieces such as pipes, shafts, and rods. Integrating advanced CNC control technology and hydraulic servo systems, it achieves automatic and efficient machining of complex processes, making it a core equipment in industries such as oil & gas, plumbing, machinery manufacturing, and automotive parts production.

- Pipe and Tube Thread Machining: As the core application of the QK1319, it excels at internal and external thread processing (metric, inch, trapezoidal, buttress threads) for various pipes. It is widely used in oil pipelines, natural gas transmission pipelines, water supply and drainage pipes, and industrial pipeline systems, processing materials including carbon steel, stainless steel, alloy steel, and non-ferrous metals.

- Shaft and Rod Precision Machining: Beyond pipe processing, it is highly capable of producing precision shafts, stepped shafts, and cylindrical rods for mechanical transmission systems, automotive chassis components, and electrical equipment. It can complete turning, boring, grooving, and facing operations in one setup, ensuring dimensional accuracy and surface finish.

- Batch Production of Long Workpieces: Equipped with a large spindle bore, long-stroke Z-axis, and multi-station hydraulic turret, the QK1319 is designed for batch processing of long workpieces (up to 2000mm). The CNC system supports program storage and automatic cycle operation, reducing manual intervention and significantly improving production efficiency.

- Customized Processing for Special Industries: In the aerospace, marine, and construction industries, it is used for processing special-shaped pipes, structural rods, and connecting components. Its flexible programming capability and high positioning accuracy meet the strict requirements of special industry standards.

Batch Advantages of Equipment

- High Precision and Stability: The machine adopts a heavy-duty cast iron bed with a box-type structure and precision ground guideways, ensuring strong rigidity and vibration resistance. The high-precision ball screws on the X and Z axes and servo drive system guarantee positioning accuracy of ±0.005mm/1000mm, maintaining consistent quality during long-term batch production.

- Efficient Thread Machining Performance: Equipped with a professional thread machining system, it supports constant surface speed cutting and automatic thread compensation. The variable frequency spindle motor provides a wide speed range, adapting to different thread pitches and material hardness, achieving fast and accurate thread processing with low tool wear.

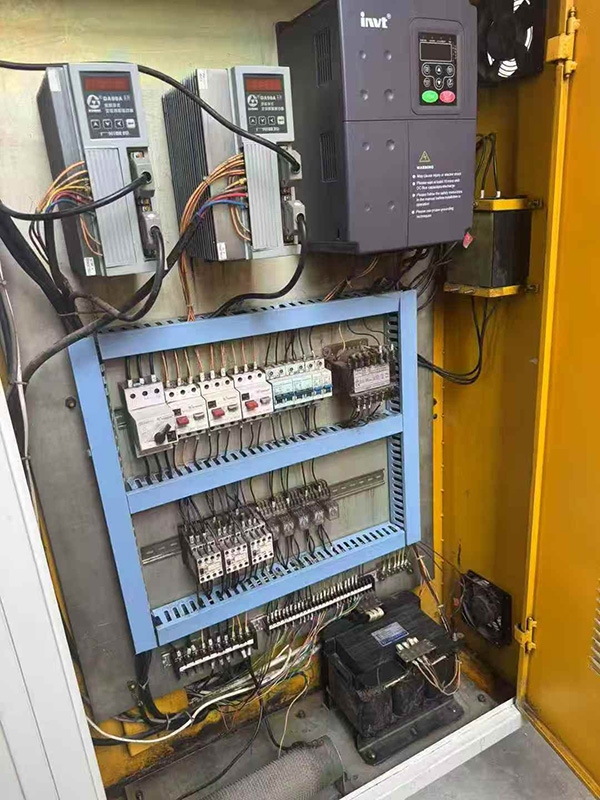

- Intelligent Automation: The advanced CNC control system (FANUC/SIEMENS/KND) features a user-friendly interface, supporting offline programming and on-site modification. The hydraulic automatic clamping and tool changing functions reduce setup time, while the automatic chip removal system (optional) keeps the working area clean and improves continuous operation capability.

- Robust and Durable Construction: Key components such as the spindle, tool post, and hydraulic system are made of high-quality materials and undergo strict testing. The machine is designed to withstand heavy-load and long-term operation, with low failure rate and easy maintenance, reducing overall operating costs.

- Cost-Effective Solution for SMEs: As a used CNC lathe, the QK1319 offers excellent cost performance. It provides the professional capabilities of a new pipe threading CNC lathe at a more economical price, enabling small and medium-sized enterprises to access high-precision automation equipment without large capital investment, enhancing market competitiveness.

7,000.00$

| Item | Specification | Item | Specification |

|---|---|---|---|

| Model Number (型号) | QK1319 | Place of Origin (产地) | China (中国) |

| Machine Type (机床类型) | CNC Pipe Threading Lathe (数控管子螺纹车床) | Brand Name (品牌) | TBD / Various Brands (待确定 / 多种品牌) |

| Max. Swing Diameter Over Bed (最大加工直径) | Φ520mm | Max. Cutting Diameter (最大切削直径) | Φ190mm |

| Max. Cutting Length (最大切削长度) | 1500mm / 2000mm (可选) | Spindle Bore (主轴通孔直径) | Φ82mm / Φ105mm (可选) |

| Spindle Speed Range (主轴转速范围) | 10-2000 rpm (变频无级调速) | Tool Post Type (刀架类型) | 4/6-station Hydraulic Turret (4/6 工位液压刀塔) |

| X-axis Travel (X 轴行程) | 280mm | Z-axis Travel (Z 轴行程) | 1550mm / 2050mm (可选) |

| Rapid Traverse Rate (快移速度) | X: 8 m/min, Z: 10 m/min | Positioning Accuracy (定位精度) | ±0.005 mm/1000mm |

| Control System (控制系统) | FANUC 0i-TB / SIEMENS 802D / KND K1Ti | Motor Power (电机功率) | 11 kW (主电机) + 2.2 kW (进给电机) |

| Tailstock Quill Diameter (尾座套筒直径) | Φ65mm | Tailstock Travel (尾座行程) | 120mm |

| Weight (重量) | Approx. 3500-4200 kg | Overall Dimensions (LWH) (外形尺寸) | 3500mm x 1800mm x 1700mm (示例) |

| Key Selling Points (核心卖点) | High Precision, Thread Machining Expert, High Efficiency, Stable Performance, Cost-Effective | Warranty (质保) | 3 Months (Parts Only) |

| Machinery Test Report (机械检测报告) | Available Upon Request | Video Outgoing-Inspection (出货视频) | Available Upon Request |

| Thread Processing Range (螺纹加工范围) | Metric/Inch/Trapezoidal/Buttress Threads | Cooling System (冷却系统) | High-Pressure Circulating Cooling System |

Don’t miss your opportunity-our best machines go fast.