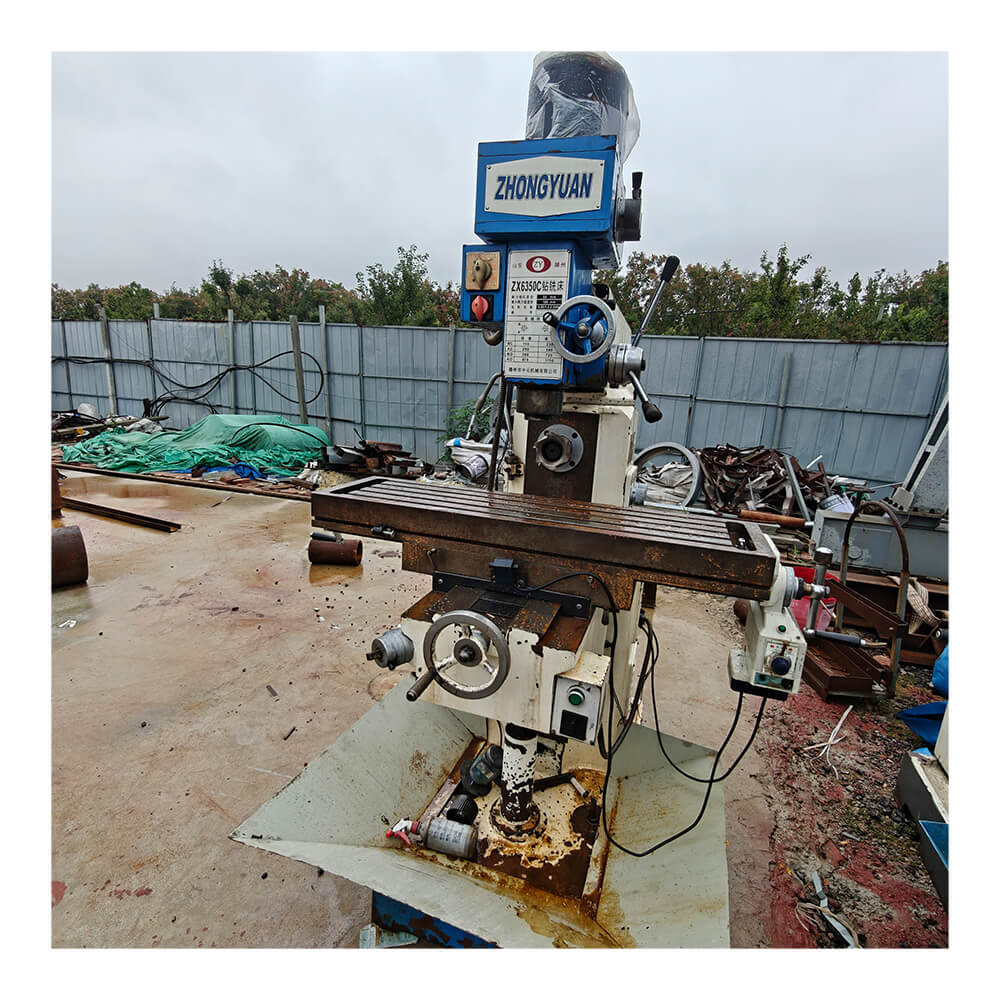

Milling machine ZX6350C

Core Application Scenarios

The ZX6350C is a robust and versatile vertical milling machine, engineered for precision machining of a wide range of metal components. Its vertical spindle configuration and rigid construction make it an essential tool in machine shops, tool rooms, and small to medium-sized manufacturing enterprises.

- Flat and Contour Milling: This machine excels at milling flat surfaces, slots, grooves, and complex contours on workpieces. It is widely used for machining parts such as gear blanks, cams, brackets, and dies, where precise surface finish and dimensional accuracy are required.

- Drilling and Tapping: Beyond milling, the ZX6350C can perform drilling, reaming, and tapping operations when equipped with appropriate attachments. This multi-functionality eliminates the need for multiple machines, saving floor space and increasing operational efficiency.

- Small Batch and Prototype Production: Its ease of setup and operation makes it ideal for small batch production runs and prototype development. Machinists can quickly adjust tooling and feeds to accommodate different part designs, reducing lead times for new projects.

- Maintenance and Repair Work: The ZX6350C is also a valuable asset in maintenance workshops for repairing and fabricating replacement parts for machinery and equipment, ensuring minimal downtime in production processes.

Batch Advantages of Equipment

- Superior Rigidity and Stability: The machine features a heavy-duty cast iron bed and column, providing exceptional rigidity and vibration damping. This ensures stable cutting performance even under heavy loads, resulting in consistent part quality and extended tool life.

- Precision and Versatility: Equipped with high-precision spindle bearings and hardened, ground guideways, the ZX6350C delivers excellent positioning accuracy and repeatability. Its variable spindle speeds and feed rates allow it to handle a diverse range of materials, from aluminum to hardened steel.

- User-Friendly Operation: The manual control system is intuitive, with clearly marked handwheels and levers for precise table movements and spindle adjustments. This makes it accessible to operators of varying skill levels, reducing training time and operational errors.

- Cost-Effective Solution: As a used machine, the ZX6350C offers an excellent balance between performance and cost. It provides the capabilities of a modern vertical milling machine at a fraction of the price of a new unit, making it an attractive investment for businesses looking to enhance their machining capabilities without a significant capital expenditure.

1,250.00$

| Item | Specification | Item | Specification |

|---|---|---|---|

| Model Number (型号) | ZX6350C | Place of Origin (产地) | China (中国) |

| Machine Type (机床类型) | Vertical Milling Machine (立式铣床) | Brand Name (品牌) | TBD / Various Brands (待确定 / 多种品牌) |

| Table Size (工作台尺寸) | 1250mm x 320mm | Table Travel (工作台行程) | X: 700mm, Y: 320mm, Z: 400mm |

| Spindle Taper (主轴锥度) | ISO 50 / Morse Taper No.5 | Spindle Speed Range (主轴转速范围) | 40-2000 rpm (12 speeds) |

| Motor Power (电机功率) | 4.0 kW / 5.5 kW (主电机) | Feed Rate (进给速度) | X, Y: 12-1200 mm/min, Z: 8-800 mm/min |

| Max. Cutting Force (最大切削力) | Approximately 3.5 kN | Max. Workpiece Weight (最大工件重量) | 500 kg |

| Overall Dimensions (L*W*H) (外形尺寸) | 1800mm x 1500mm x 2200mm | Weight (重量) | Approx. 1800 kg |

| Control System (控制系统) | Manual / Optional CNC (手动 / 可选数控) | Key Selling Points (核心卖点) | High Rigidity, Versatile, Easy Operation, Cost-Effective |

| Warranty (质保) | 3 Months (Parts Only) | Machinery Test Report (机械检测报告) | Available Upon Request |

| Video Outgoing-Inspection (出货视频) | Available Upon Request |

Don’t miss your opportunity-our best machines go fast.