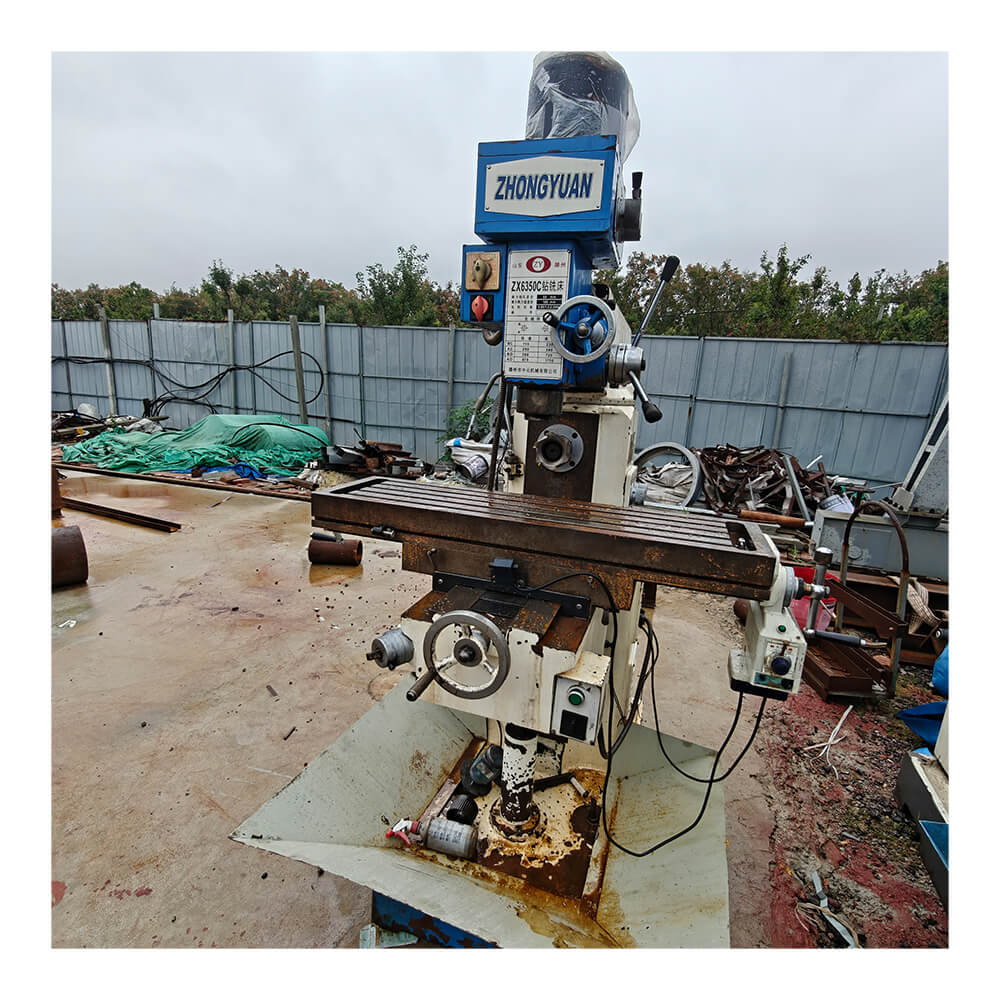

Milling Machine ZX6350C

The ZX6350C is a versatile and high-performance vertical – horizontal drilling and milling machine, widely recognized in the metalworking industry for its reliable performance and multi – functional capabilities. It integrates drilling, milling, boring, tapping and other machining functions, making it an ideal choice for single – piece production, small – batch processing, as well as maintenance and repair work in fields like instrument manufacturing, mechanical engineering, and building decoration. Below is a detailed breakdown of its core advantages and characteristics:

Powerful Machining Capabilities

The machine excels in various machining tasks with outstanding processing indexes. It can achieve a maximum drilling diameter of 50mm, a maximum vertical milling diameter of 25mm, and a maximum horizontal milling width of 100mm. Additionally, it supports a maximum boring diameter of 120mm and a maximum tapping diameter of M16, which is capable of handling the processing needs of most common metal workpieces.

It is equipped with both vertical and horizontal main motors. The vertical main motor power is available in 0.85kw or 1.5kw options, while the horizontal main motor power reaches 2.2kw. This power configuration ensures sufficient torque during high – load machining processes such as heavy – duty milling and large – diameter drilling, maintaining stable operation without power loss.

3,000.00$

| Category | Item | Specifications |

|---|---|---|

| Spindle Related | Spindle Taper | R8 / ISO 40 / MT 4 (optional based on configuration) |

| Vertical Spindle Speed Range | 115 - 1750 rpm, 8 steps | |

| Horizontal Spindle Speed Range | 40 - 1300 rpm, 16 steps (partial models 38 - 1310 rpm, 12 steps) | |

| Spindle Quill Travel | 120 mm (vertical) | |

| Spindle Travel | 120 mm | |

| Work Table | Table Size | 1200×280 mm (partial models 1120×260 mm) |

| Maximum Travel of Table (X/Y/Z) | 700 / 260 / 400 mm (partial models 600 / 270 / 360 mm) | |

| Feeding Range of Longitudinal & Cross Travel | 24 - 720 mm/min, 8 grades (partial models 24 - 402 mm/min, 9 grades) | |

| Maximum Load of Table | 250 kg (for 1120×260 mm table) | |

| Distance Parameters | Distance from Vertical Spindle to Work Table | 80 - 460 mm (partial models 100 - 460 mm) |

| Distance from Horizontal Spindle to Table | 0 - 380 mm (partial models 0 - 360 mm) | |

| Distance from Spindle to Column | 200 - 500 mm | |

| Distance from Horizontal Spindle Axis to Arm Bottom | 175 mm | |

| Motor Power | Vertical Main Motor Power | 0.85 / 1.5 kw |

| Horizontal Main Motor Power | 2.2 kw | |

| Feed Motor Power | 0.37 kw | |

| Coolant Motor Power | 0.4 kw (partial models 0.04 kw) | |

| Overall Dimension | Overall Size | 1220×1120×2095 mm (partial models 1660×1450×2150 mm) |

| Weight | Net Weight (N.W) | 1200 kg |

| Gross Weight (G.W) | 1350 kg | |

| Processing Capacity | Maximum Drilling Diameter | 50 mm |

| Maximum Vertical Milling Diameter | 25 mm | |

| Maximum Horizontal Milling Width | 100 mm | |

| Maximum Boring Diameter | 120 mm | |

| Maximum Tapping Diameter | M16 | |

| Standard Accessories | Standard Configuration | 160 mm machine vice, φ16 drill chuck, mill chuck, reduction sleeve, draw bar, spindle arbor, 2 horizontal milling hilts, wrenches, operation manual, etc. |

Don’t miss your opportunity-our best machines go fast.